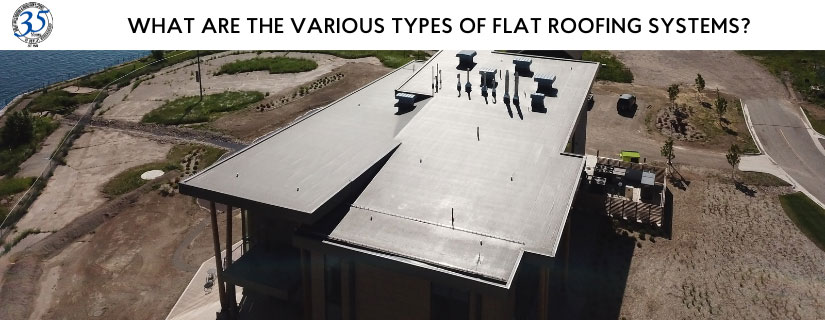

When it comes to commercial roofing, building owners have lots of options.

Built-up roofing (BUR) systems have been in use in the U.S. for more than a century. They are so named because they are essentially “built” on the rooftop by the contractor, by alternating multiple layers of asphalt or tar between layers of felt or synthetic materials. They are often covered with gravel for protection from the elements.

The 1960s and 70s saw the development of alternatives to BUR, notably single-ply membrane roofing systems. Single-ply membranes are flexible sheets that can be manufactured from a variety of synthetic materials. Here are the most common single-ply options:

Modified bitumen membranes. These evolved from built-up roofing and are factory-manufactured layers of asphalt that are “modified’ using plastic or rubber components and reinforced with a fabric layer.

Thermoset membranes are essentially rubber, known as Ethylene Propylene Diene Monomer – EPDM. Thermoset roofing materials can’t be heat welded and require adhesives for installation seaming.

TPO (thermoplastic polyolefin) is a thermoplastic membrane that combines the flexibility and weather resistance of EPDM and the heat-weldability/chemical resistance of PVC.

PVC (polyvinyl chloride) is another thermoplastic choice. It provides excellent fire, oil, and chemical resistance, as well as excellent weathering and seaming. Because they don’t “cure” on the rooftop, they remain weldable for years after initial installation.

At Great Lakes Roofing, we prefer to install PVC single-ply systems manufactured by Duro-Last right here in Michigan. Billions of Duro-Last roof membrane has been installed across the United States, dating back more than 30 years. Not only do we believe the roof membrane is the best on the market, but we know that Duro-Last stands behind its product. Call us today at (906) 647-2916 for a free quote.